Basic Info.

Model NO.

(QDTJ-B-400)

Max Width of Bronzing

400mm

Max Speed of Machine

80m/Min

Power of Traction Motor

4kw

Weight

2000kg

Total Power

14kw

Transport Package

Wooden Box

Specification

5700*1800*2250mm

Trademark

qiangda

Origin

Zhejiang

HS Code

8443170000

Production Capacity

500/Year

Product Description

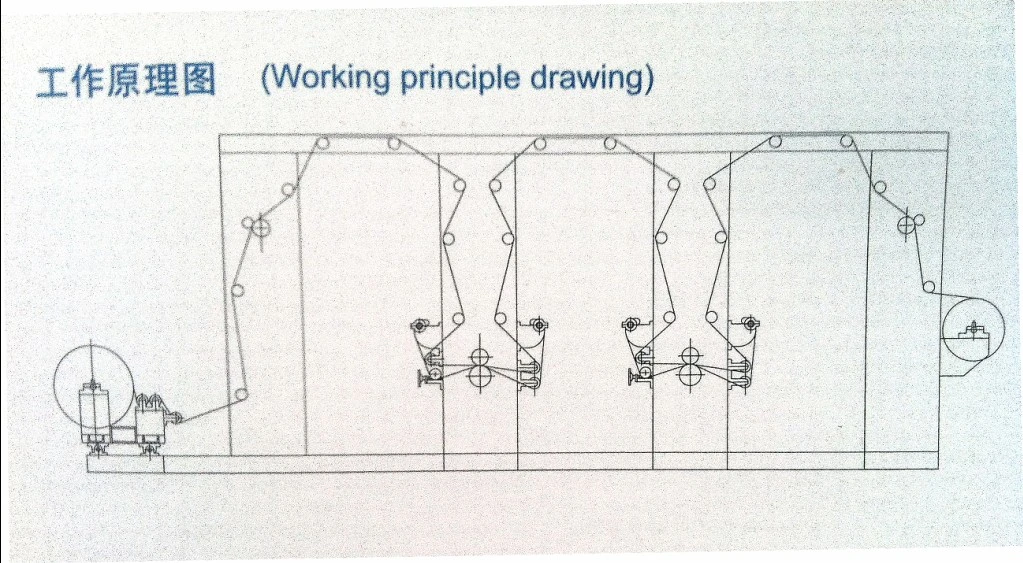

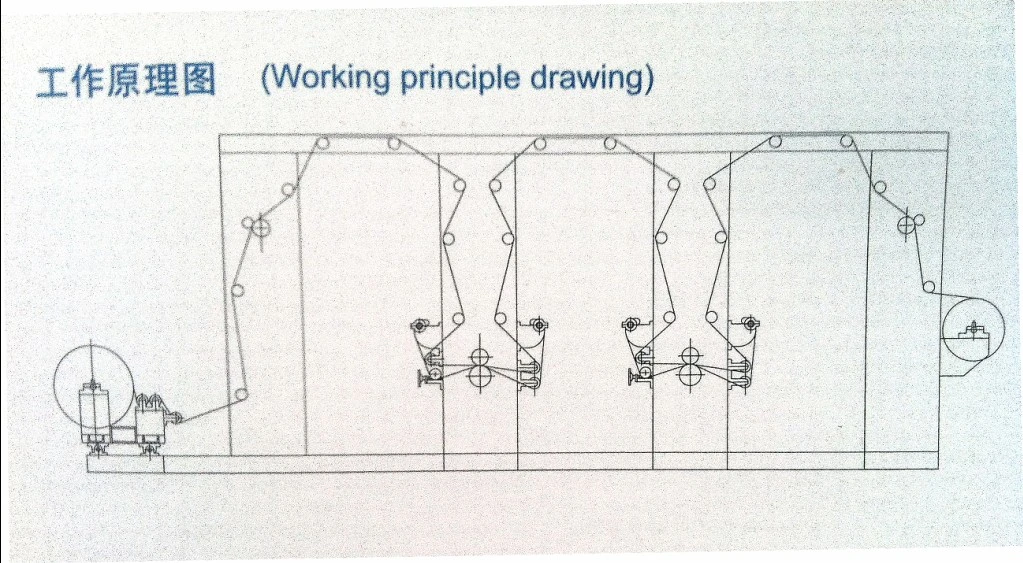

QDTJ-B-400 Model Computer Error-correction Yew Paper Bronzing Machine

Technical Parameters

- Bronzing color number: 2 colors

- General printing base material: yew paper and materials with super-quality for bronzing

- Max width of bronzing: 400mm

- Max speed of machine: 80m/min

- Speed of bronzing: 5-65m/min

- Lengthways comprehensive colored precision: ± 0.2mm

- Diameter of bronzing roller: ¢90mm-180mm

- Max width of bronzing roller: 430mm

- Width of guide roller: 430mm

- Diameter of rewinding and winding: max ¢540mm

- Main drive motor: 2.2kw frequency motor

- Power: 16.2kw

- Weight: approx.2500kg

- Overall dimensions: 6200(L)×2200(W)×2300(H)mm

- Machine color: offwhite

Machine disposed

- Rewinding device

- Rewinding frame

- Photoelectric error correction

- Right and left adjustment for base material: manual operation scope: ±20mm

- Max diameter of rewinding:¢540mm

- Scope of tension control: 3-25kg

- 5kg magnetic powder brake(made in Ningxia)

- Specification of paper core:¢76mm

- Rewinding automatic eternal tension(made in Wenzhou)

- Air blowing rewinding shaft

- Bronzing film rewinding frame

- Right and left adjustment for base material: manual operation scope:±20mm

- Max diameter of rewinding: ¢500mm

- Manual tension controller

- 1.5kg magnetic powder clutch (made in Ningxia) 2 pieces

- Specification of paper core: ¢76mm

- Air blowing rewinding shaft

- Bronzing unit

- Bronzing plate roller

- Right and left adjustment for bronzing plate roller: manual operation, scope: ±20mm

- Bronzing plate: circular plate bronzing type

- Transmission box: gearing box transmission

- Bronzing pressure roller

- Method: pneumatic press, (the pressure printing force can be adjusted freely)

- Max pressure: 300kg

- Specification of bronzing roller: ¢130mm (silicon rubber hardness: 70-90)

- Bronzing plate heating manner

- Outboard oil heating recycling manner

- Oil heating box 2 pieces

- Heating power: 3.2kw (per unit) 2sets

- Cycling oil pump: 2pieces (2×2.2kw)

- Temperature control: automatic eternal temperature control (2sets)

- Temperature adjustment: 5-280°

- Paper pre-heating oven (3.2kw)

- Aluminum guide roller

- Guide roller: made in Shanghai

- Winding unit

- Winding material draw:

- Structure: active draw, manual pressure firmly

- Drive method: main motor equipped with 2.5kg magnetic powder clutch(made in Ningxia) 1piece

- Finished product winding frame

- Structure: turning style double working position

- Paper core installation method: winding air blowing style ¢76mm

- Right and left adjustment for base material: scope ±20mm

- Arm turning: manual turning

- Winding motor: main motor equipped with 5kg magnetic powder clutch (made in Xingxia) 1piece

- Tension control: tension controller

- Tension scope: 3-20kg

- Diameter: max ¢540mm

- Diameter of paper core: ¢76mm

- Bronzing film winding frame

(2)Max diameter: ¢400mm

- Manual tension controller

- 1.5kg magnetic powder clutch (made in Ningxia) 2pieces

- Specification of paper core:¢76mm

- Completing equipment (solve it by users themselves)

- Heating conductive oil

| No. | Title | Spec & Code | Unit | Amount | Remark |

| 1 | Tads for machine | Piece | |||

| 2 | Double head wrench | 12×14 | Piece | 1 | |

| 3 | Double head wrench | 14×17 | Piece | 1 | |

| 4 | Double head wrench | 19×22 | Piece | 1 | |

| 5 | Wrench | Pieces | 2 | ||

| 6 | Inner hexagonal wrench | Set | 1 | ||

| 7 | "-" shape screw driver | Piece | 1 | ||

| 8 | "+"shape screw driver | Piece | 1 | ||

| 9 | Silica gel roller | 400mm | Pieces | 2 | |

| 10 | Ink pump | Piece | 1 | ||

| 11 | Bronzing plate shaft gear | Pieces | 2 | ||

| 12 | Air compressor | Set | 1 | ||

| 13 | |||||

| 14 | |||||

| 15 | |||||

| 16 | |||||

| 17 | |||||

| 18 | |||||

| 19 |

Please contact me for more details.

Contact: Kathy Mob 0086 13506771772