Basic Info.

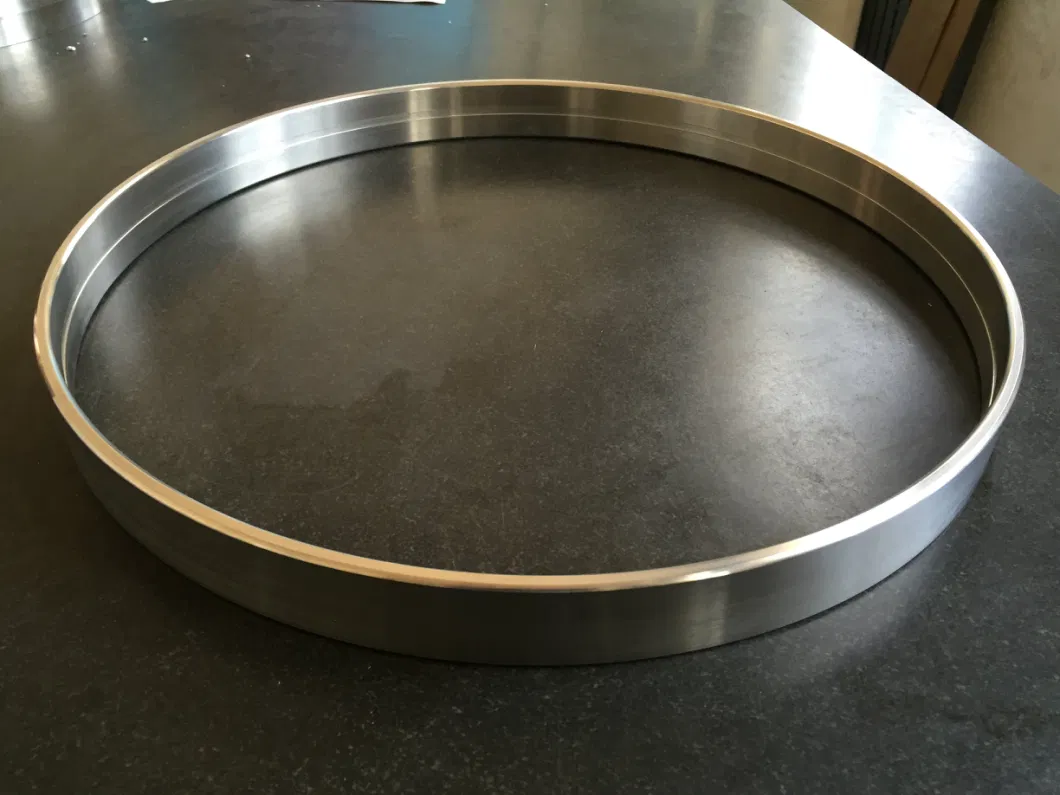

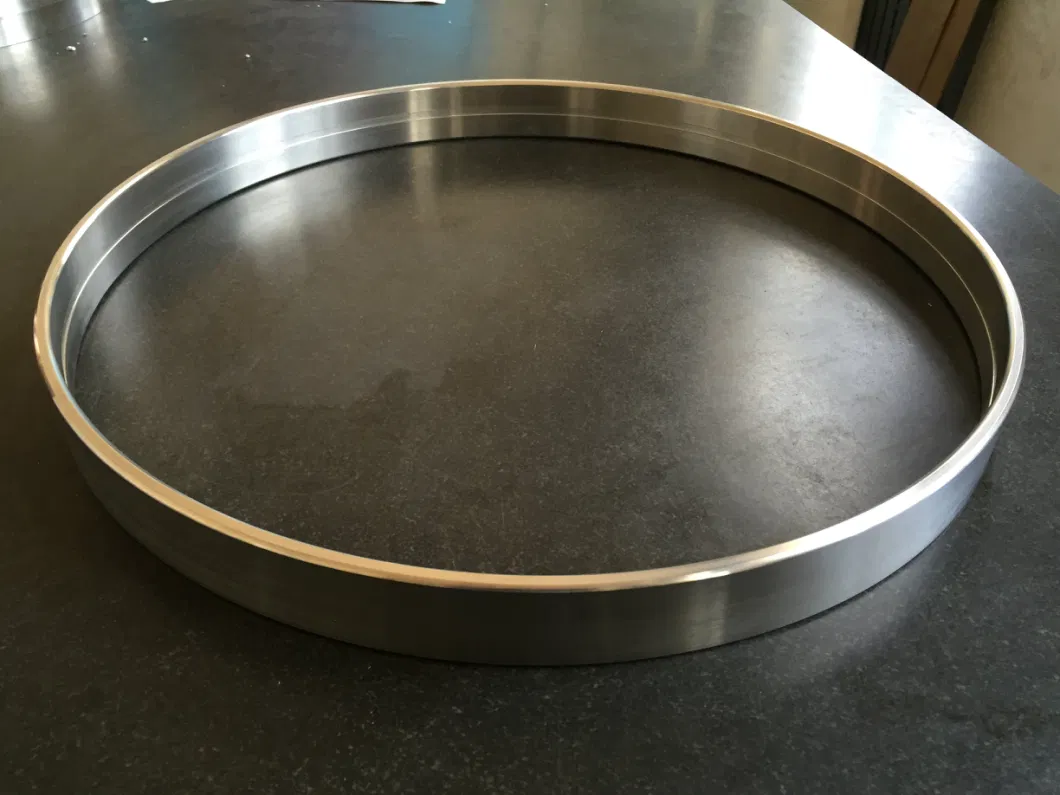

Model NO.

ring

Product Description

We can provide copper alloy plates of various materials. For example:Aluminum bronze,CuCrZr,silver copper. But not limited to the above materials. The main products of copper ring are center ring, retaining ring and end ring. We can make customized products according to customers' material, size and performance requirements.

Characteristics:

After vacuum melting and casting, the material composition is stable and uniform; The mature hot working and cold working technology combined with the heat treatment process makes the products have fine grains, uniform structure and good consistency of mechanical properties. High hardness, high conductivity and good thermal conductivity. Strong deformation resistance and high fatigue strength. No air hole, slag inclusion, sand hole and other defects, long service life.

The high-conductivity alloys of WLVM adopt large-tonnage vacuum casting technology and strict quality management procedures to precisely control the size and distribution of precipitates to ensure uniform and stable composition and structure. The hardness of HRB can reach more than 85 and the conductivity can reach more than 88% IACS. It can meet the technical requirements of high-speed cold heading. It is widely used in intelligent terminal equipment, welding equipment, special motors (rail transportation, electric power), medical equipment, and steel industry. , UHV power transmission and transformation, precision die-casting molds and other fields.

Application field:

high-speed railway/engine/subway

Characteristics:

After vacuum melting and casting, the material composition is stable and uniform; The mature hot working and cold working technology combined with the heat treatment process makes the products have fine grains, uniform structure and good consistency of mechanical properties. High hardness, high conductivity and good thermal conductivity. Strong deformation resistance and high fatigue strength. No air hole, slag inclusion, sand hole and other defects, long service life.

The high-conductivity alloys of WLVM adopt large-tonnage vacuum casting technology and strict quality management procedures to precisely control the size and distribution of precipitates to ensure uniform and stable composition and structure. The hardness of HRB can reach more than 85 and the conductivity can reach more than 88% IACS. It can meet the technical requirements of high-speed cold heading. It is widely used in intelligent terminal equipment, welding equipment, special motors (rail transportation, electric power), medical equipment, and steel industry. , UHV power transmission and transformation, precision die-casting molds and other fields.

Application field:

high-speed railway/engine/subway