Basic Info.

Model NO.

PB44

Standard

ASTM

Lead Time

20 Days

Shipping Way

by Air, by Sea

Composition

Cu94sn6%

Thickness

0.1-2.0mm

with

10-900mm

Transport Package

Wooden Box or Pallet

Specification

According to specification

Trademark

INT

Origin

China

HS Code

7409310000

Production Capacity

50ton/Week

Product Description

Cusn6 CDA519 C51900 Phosphor Bronze Alloys

Phosphor bronze factory, more than 12 years manufacture experience, attained ISO9001, work on OEM and ODM projects..

It is used for connector and current-carrying springs in contacts. Among the 4-8% tin bronze C51900 exhibits a high electrical conductivity, the highest reachable strength is significantly higher than C51000. By means of an additional further tempering after the cold forming process the bendability can be further improved.

Due to the higher strength and springiness and good workability, C51900 is used for all types of springs as well as for flexible metal hoses.

Temper: O, 1/4H, 1/2H, H, EH,SH

Different countries' Standard comparison table of Phosphor bronze

![]()

• High Strength

• Good Formability

• Excellent Connector for Telecommunication Spring Applications

• Low Memory

• Ideal Shear / Yield Ratio

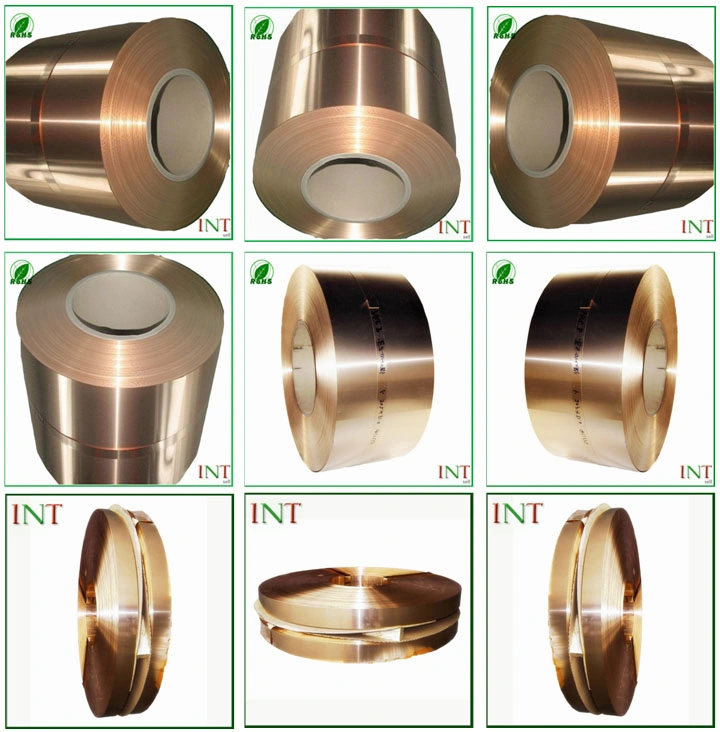

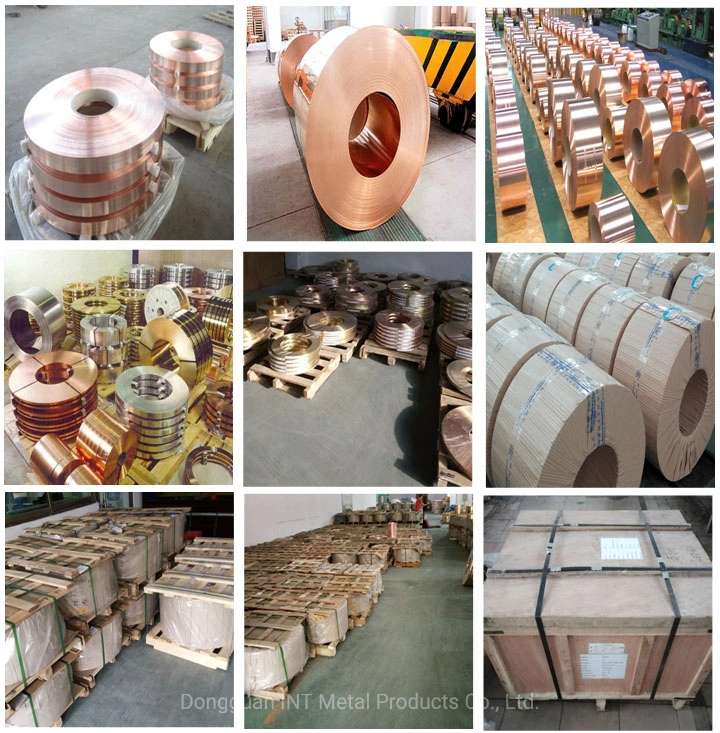

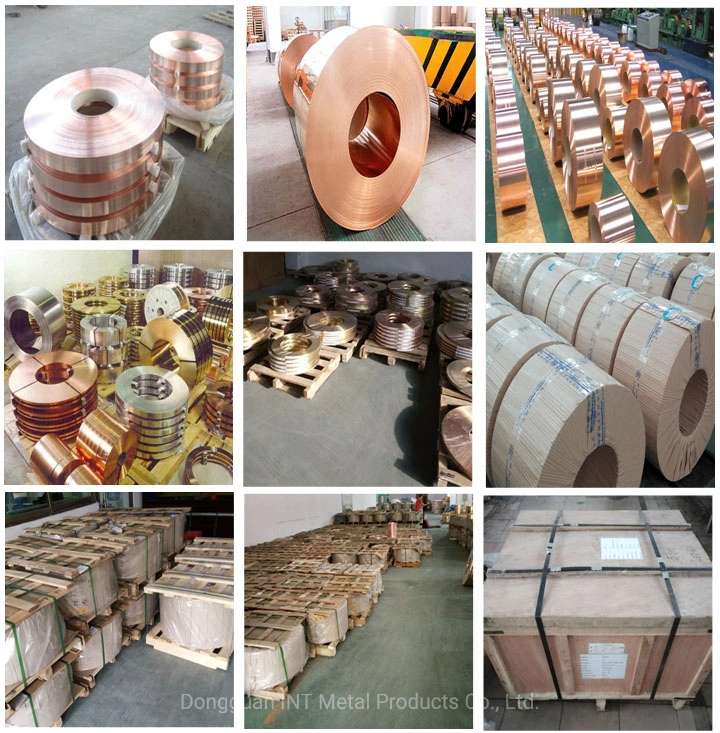

7. Manufacture plant of C51900 CuSn6 Phosphor Bronze strip

8. Tests and inspection for C51900 CuSn6 Phosphor Bronze strip Test instrument : Metallographic Microscope; Digital Light Processor; Strength Tester; Hardness Tester.

10. Packing and shipping for C51900 CuSn6 Phosphor Bronze strip

Packing:

First wrapped by anti-rust paper, second wrapped by plastic film, then packed by wooden box or wooden pallet ..

Shipping:

We will choose the best way according to customer's requests.

1. By Air, to the indicated airport.

2. By Express (FedEx, UPS, DHL, TNT, EMS), to the indicated address.

2. By Sea, to the indicated sea port.

a1. Do you have ISO certificate?

Yes, we obtained ISO9001

a2. How long is your delivery time for C51900 CuSn6 Phosphor Bronze strip ?

If the master coil is available, 3-7 days do slitting will be ready , if not, will need 20-25 days for new production.

a3. Can you help us to choose suitable material?

Yes, we can recommend the most suitable material according to your application.

a4. How do you control quality?

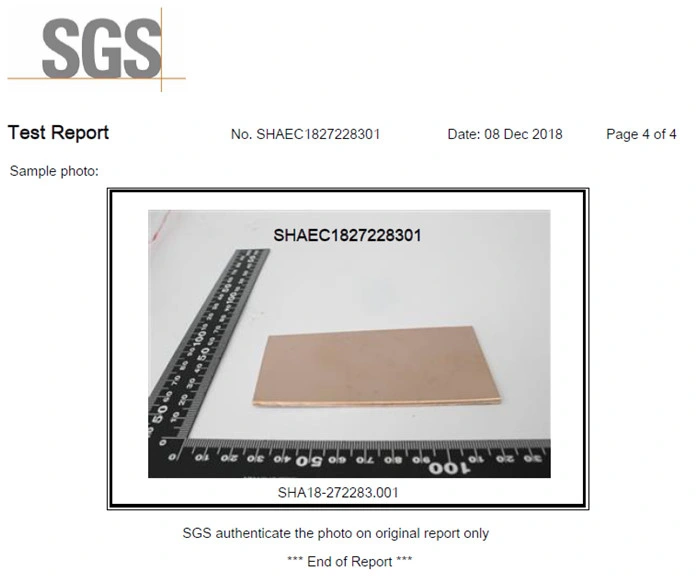

We produce strictly according to customer's drawings and requests, here are strict control plan in every process, full check of each parts, strive to provide customer 100% quality products, ROHS/SGS test report, material certificate are available.

a5. Do you provide sample? Free or charge?

Yes, if the sample in stock available, free of charge, if not, need to charge some mfg cost.

Phosphor bronze factory, more than 12 years manufacture experience, attained ISO9001, work on OEM and ODM projects..

1. Introduction of the C51900 CuSn6 PB103 Phosphor Bronze strip

C51900/ CuSn6 Phosphor Bronze, which is a 6% tin bronze distinguished by a very good combination of strength and electrical conductivity. It is used for connector and current-carrying springs in contacts. Among the 4-8% tin bronze C51900 exhibits a high electrical conductivity, the highest reachable strength is significantly higher than C51000. By means of an additional further tempering after the cold forming process the bendability can be further improved.

Due to the higher strength and springiness and good workability, C51900 is used for all types of springs as well as for flexible metal hoses.

2. Grade and temper for C51900 CuSn6 Phosphor Bronze strip

Grade: C5191, C51900, CDA519, C519, PB103, CuSn6 Temper: O, 1/4H, 1/2H, H, EH,SH

3. Chemical composition of C51900 CuSn6 Phosphor Bronze strip

Chemical composition | Grade | Cu | Fe | Pb | P | Sn | Zn |

| C51900 | Balance | 0.1max | 0.05max | 0.03-0.35 | 5.5 - 7.0 | 0.3max |

Different countries' Standard comparison table of Phosphor bronze

| GB | DIN | EN | ISO | UNS | JIS | ||

| - | CuSn5 | 2.1018 | CuSn5 | CW451K | CuSn5 | C51000 | C5102 |

| QSn6.5-0.1 | CuSn6 | 2.1020 | CuSn6 | CW452K | CuSn6 | C51900 | C5191 |

| QSn8-0.3 | CuSn8 | 2.1030 | CuSn8 | CW453K | CuSn8 | C52100 | C5210 |

4. Mechanical properties for C51900 CuSn6 Phosphor Bronze strip

Mechanical properties C5191 HV Tensile strength Elongation

M 90-110 310-395 >40

H/4 110-150 395-490 >35

H/2 150-180 490-600 >20

H 180-210 590-680 >10

EH 210-230 >635 >5

5. Characteristic of C51900 CuSn6 Phosphor Bronze strip

M 90-110 310-395 >40

H/4 110-150 395-490 >35

H/2 150-180 490-600 >20

H 180-210 590-680 >10

EH 210-230 >635 >5

5. Characteristic of C51900 CuSn6 Phosphor Bronze strip

• High Strength

• Good Formability

• Excellent Connector for Telecommunication Spring Applications

• Low Memory

• Ideal Shear / Yield Ratio

6. Application of C51900 CuSn6 Phosphor Bronze strip

| Electrical | Stamped Parts,springs, Components of Electrical Engineering, Terminals,Contacts, Switch Parts, Electromechanical Spring Components, Resistance Wire, Electrical Flexing Contact Blades, Electrical Connectors, Electronic Connectors, Wire Brushes, Electronic and Precision Instrument Parts, Fuse Clips, Terminal Brackets. |

| Industrial | Bellows, Textile Machinery, Perforated Sheets, Chemical Hardware, Truss Wire, Mechanical Springs, Sleeve Bushings, Diaphragms, Clutch Disks, Bourdon Tubes, Beater Bar, Welding Rods, Pressure Responsive Elements, Sprinkler Parts, Automotive Parts |

7. Manufacture plant of C51900 CuSn6 Phosphor Bronze strip

8. Tests and inspection for C51900 CuSn6 Phosphor Bronze strip

9. Mill certificate for C51900 CuSn6 Phosphor Bronze strip

10. Packing and shipping for C51900 CuSn6 Phosphor Bronze strip

Packing:

First wrapped by anti-rust paper, second wrapped by plastic film, then packed by wooden box or wooden pallet ..

Shipping:

We will choose the best way according to customer's requests.

1. By Air, to the indicated airport.

2. By Express (FedEx, UPS, DHL, TNT, EMS), to the indicated address.

2. By Sea, to the indicated sea port.

11. Questions and Answers

a1. Do you have ISO certificate?

Yes, we obtained ISO9001

a2. How long is your delivery time for C51900 CuSn6 Phosphor Bronze strip ?

If the master coil is available, 3-7 days do slitting will be ready , if not, will need 20-25 days for new production.

a3. Can you help us to choose suitable material?

Yes, we can recommend the most suitable material according to your application.

a4. How do you control quality?

We produce strictly according to customer's drawings and requests, here are strict control plan in every process, full check of each parts, strive to provide customer 100% quality products, ROHS/SGS test report, material certificate are available.

a5. Do you provide sample? Free or charge?

Yes, if the sample in stock available, free of charge, if not, need to charge some mfg cost.