Basic Info.

Model NO.

customized

HS Code

8454909000

Production Capacity

5000

Product Description

The product is a patented hard grade aluminium bronze. Its exceptional hardness makes it a unique material. However, this extreme hardness means fragility and machinability difficulties. This alloy has very limited uses and machinability, but it gives exceptional results.

APPLICATIONS

Stainless steel drawing dies, forming rolls under great stresses and extreme pressures are the most typical applications for this alloy.

Chemical composition

Al:10.5% Fe:3.5% Other:Up to 0.5% The rest is copper

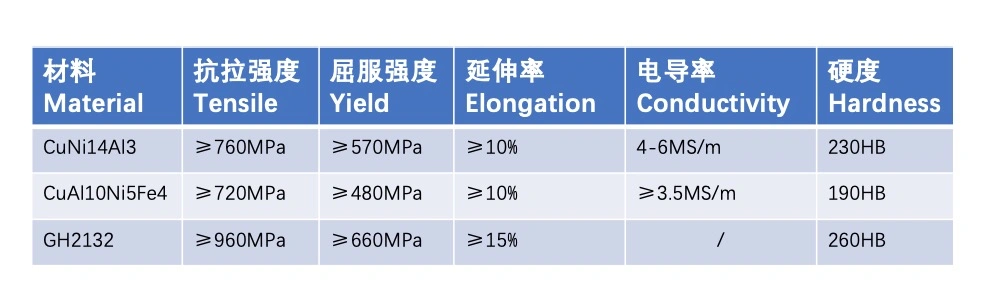

| Mechanical and physical | Units | Nominal value |

| Tensile strength R m | MPa | 793 |

| Specified non-proportional extension strength R p0.5 | MPa | 407 |

Elongation after breaking A | % | 10 |

Brinell hardness | HBW 10/3000 | 228 |

Rockwell hardness | HRB | 98 |

Reduction of area Z | % | 8 |

Compressive strength R mc | Mpa | 1069 |

Specified non-proportional compressive strength R pc0.1 | Mpa | 441 |

Compression ratio limit R pc | Mpa | 338 |

Shear strength R cm | Mpa | 427 |

Elastic modulus E | Gpa | 110 |

Charpy shock absorption energy AK | J | 11 |

Izod impact absorption power AK | J | 16.3 |

| Fatigue strength (100'000'000 times) σN | Mpa | 248 |

Density ρ | g / cm³ | 7.45 |

Coefficient of linear expansion α | 10-6 / K | 16.2 |

Thermal conductivity λ | W / m · K | 59 |

Conductivity γ | m / Ω· mm² | 7.5 |

Conductivity | % I.A.C.S. | 13 |

Specific heat capacity cp | J / g · K | 0.42 |

APPLICATIONS

Stainless steel drawing dies, forming rolls under great stresses and extreme pressures are the most typical applications for this alloy.

Chemical composition

Al:10.5% Fe:3.5% Other:Up to 0.5% The rest is copper