Basic Info.

Model NO.

SLTG

Standard

GB/T

Thickness

0.05~3.1mm

Status

Y, Y2, M, TM

Width

1-600mm

Ratio of Copper Layer

4-10%Each Side

Tolerance

10%

Transport Package

Rust-Proof Paper, Protective Film, Steel Belt Ect.

Specification

customized

Trademark

SLXCL

Origin

China

HS Code

721260000

Production Capacity

1000ton/Month

Product Description

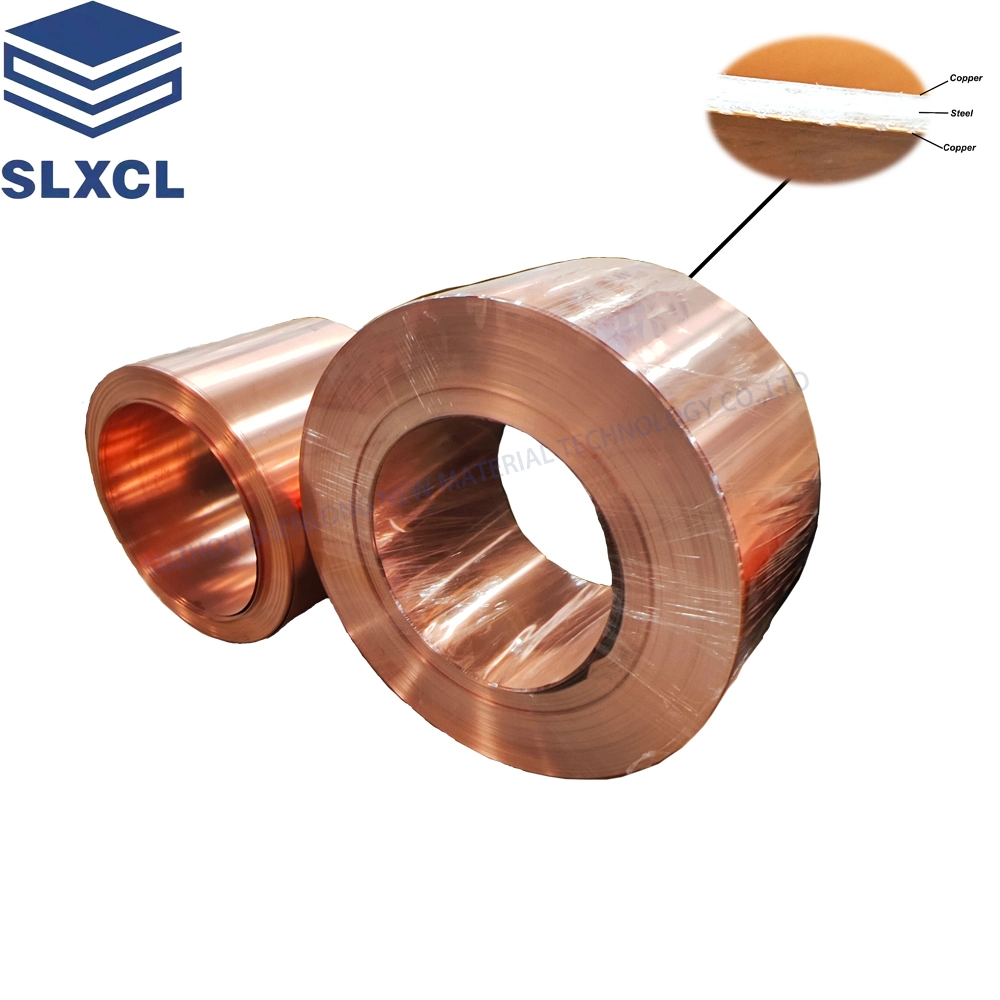

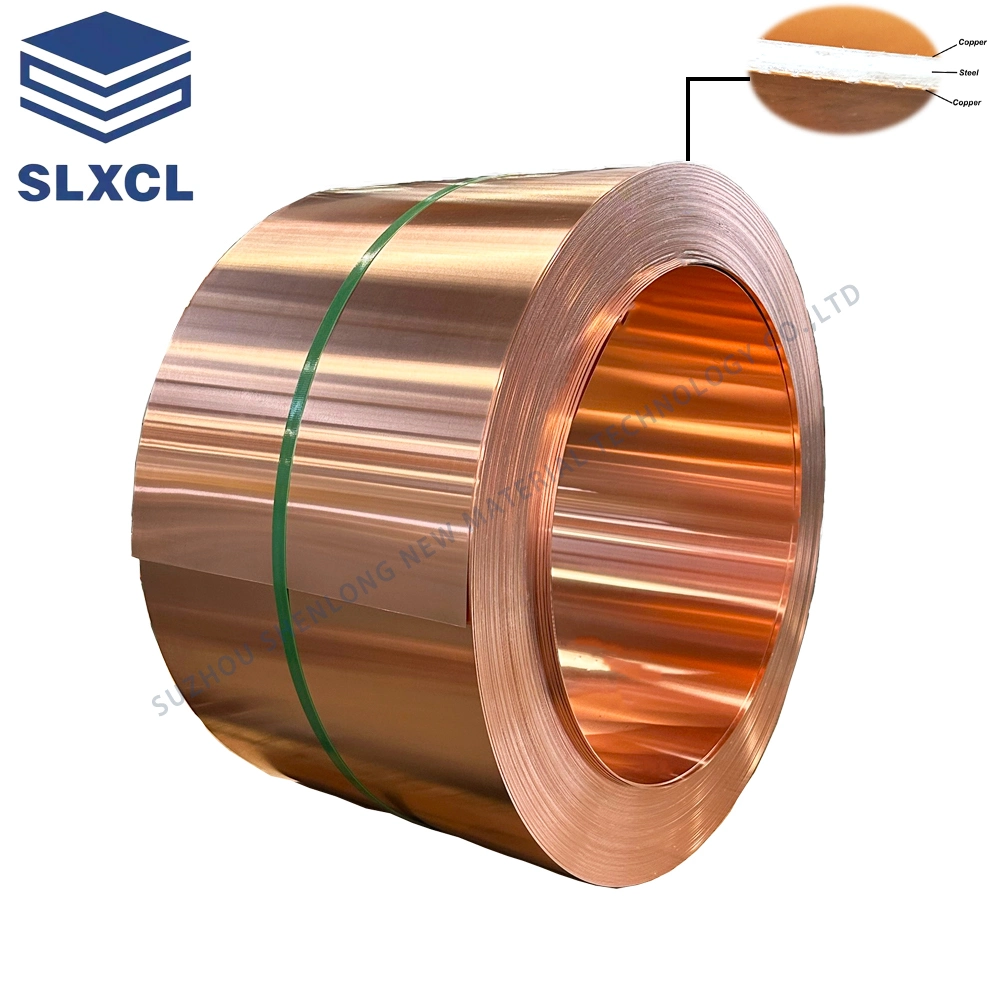

Copper Clad Steel of Shenlong

(Traditional copper substitute)

(Traditional copper substitute)

Metal composite material is a new type of material prepared by using a composite technique to achieve a strong bond at the interface of at least two or more metals. Metal laminar composite materials, while retaining the original characteristics of the matrix metal, also exhibit a "complementary effect." This effect improves the material's mechanical properties, thermoelectric properties, welding performance, formability, etc., resulting in comprehensive performance superior to the base metal.

Copper clad steel materials combine the corrosion resistance, high electrical and thermal conductivity of copper with the good welding and processing properties of steel. They are applied in fields such as aerospace, aviation, and power due to these characteristics.

Copper clad steel materials combine the corrosion resistance, high electrical and thermal conductivity of copper with the good welding and processing properties of steel. They are applied in fields such as aerospace, aviation, and power due to these characteristics.

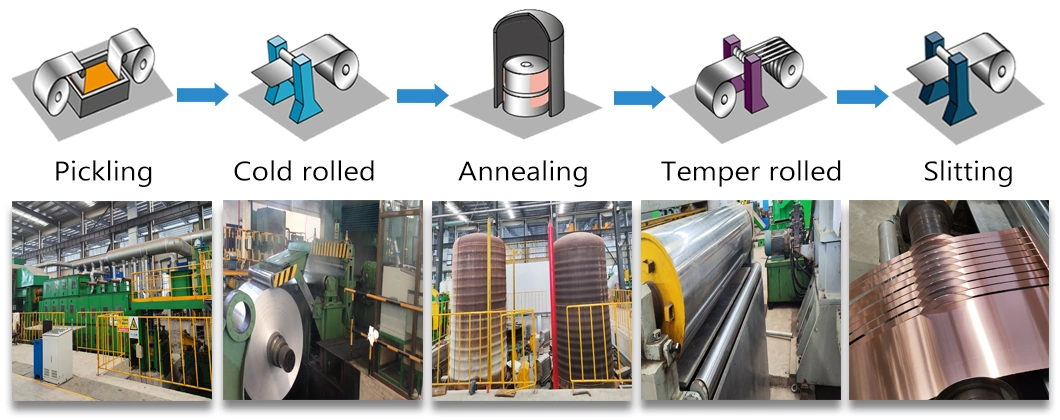

Cold Roll

Compared to the hot rolling composite method, products produced by the cold rolling composite method are diverse, have high dimensional accuracy, smooth surfaces, and excellent overall mechanical properties. The cold rolling process is simple and flexible, with strong operability. During the rolling process, oxidation at the interface does not occur, making it one of the most widely used methods currently.

Process Flow Diagram

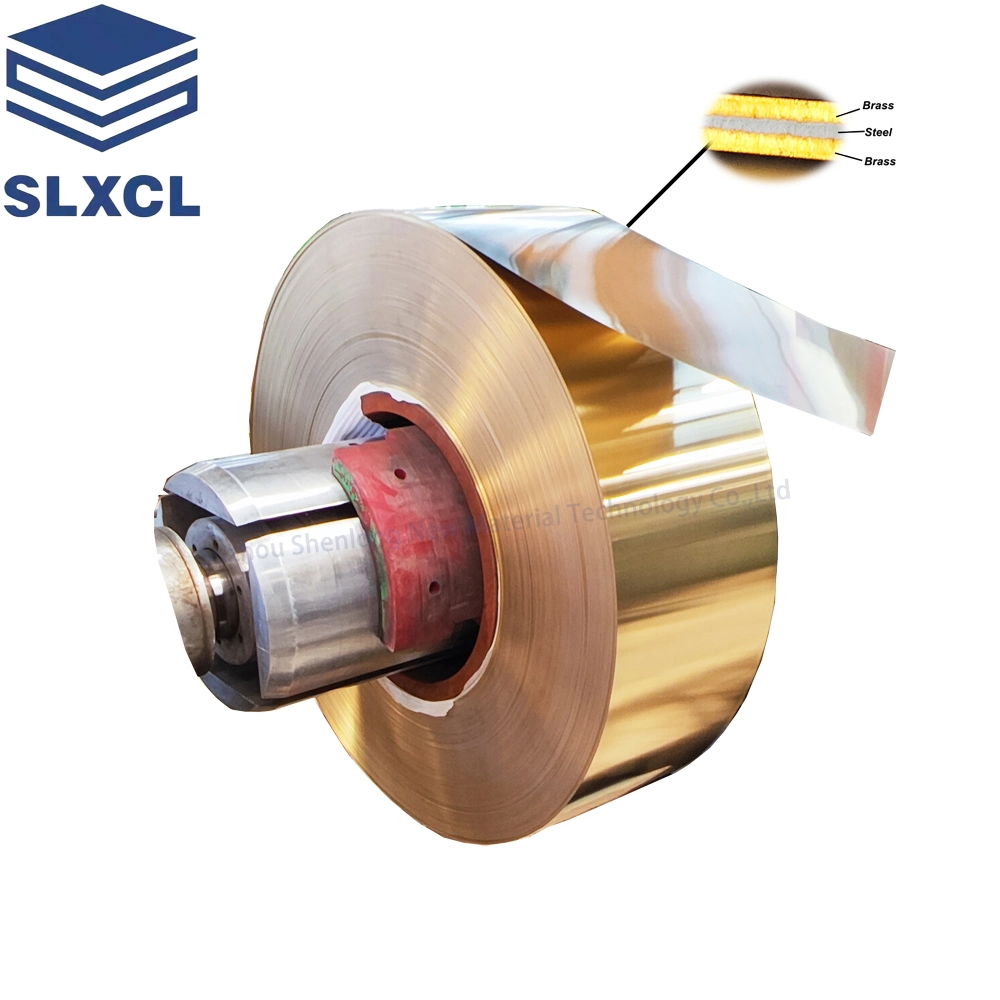

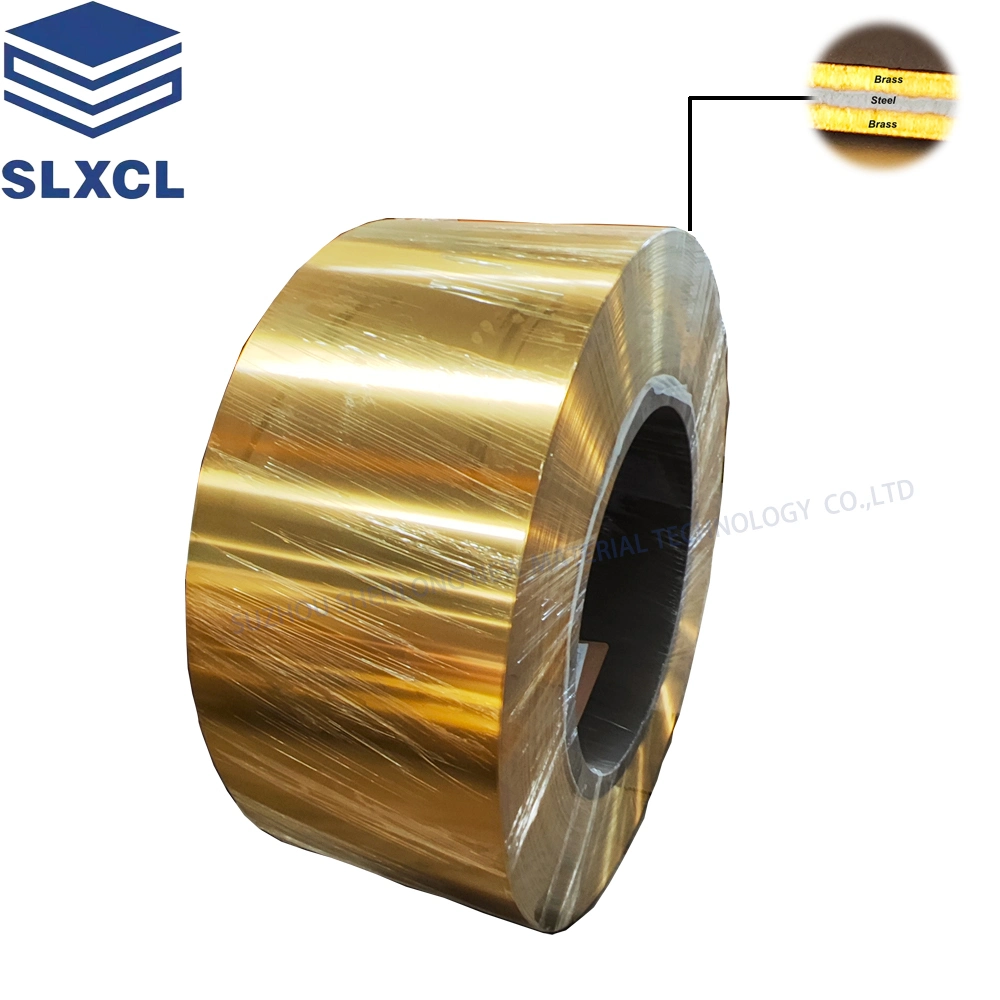

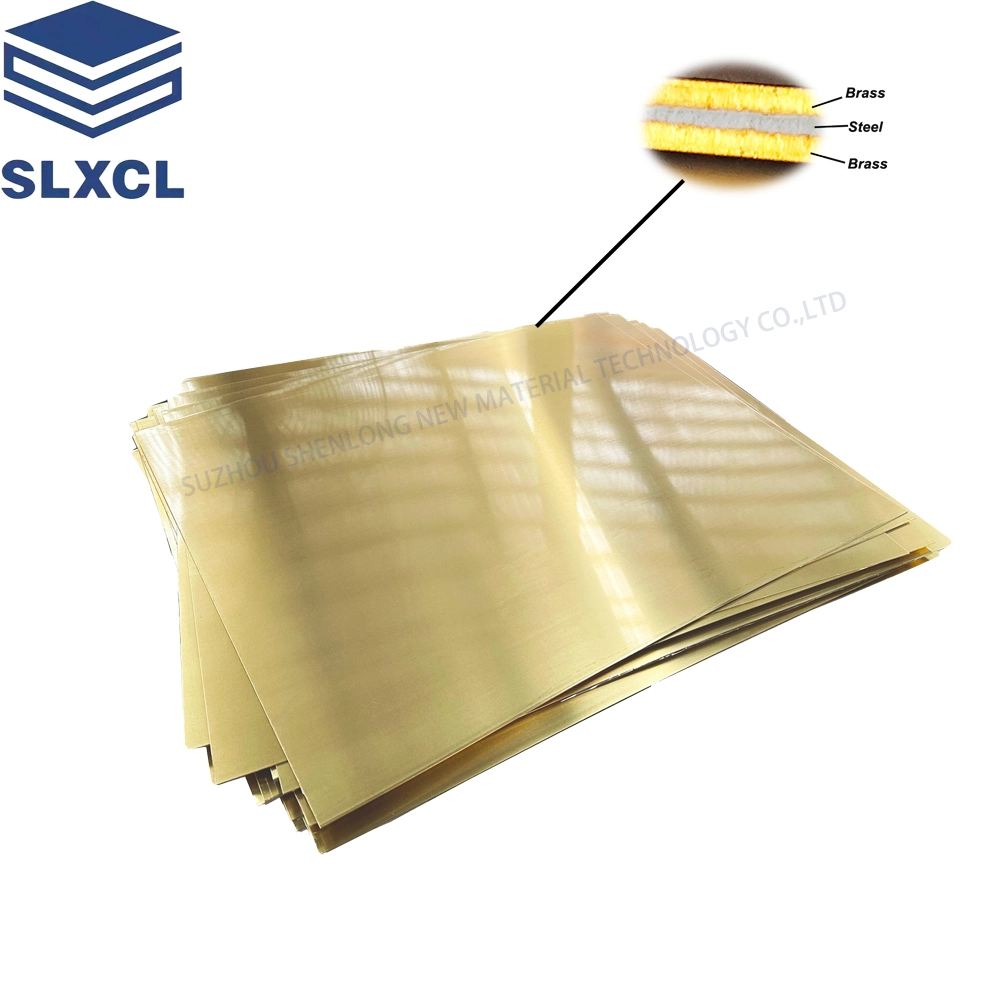

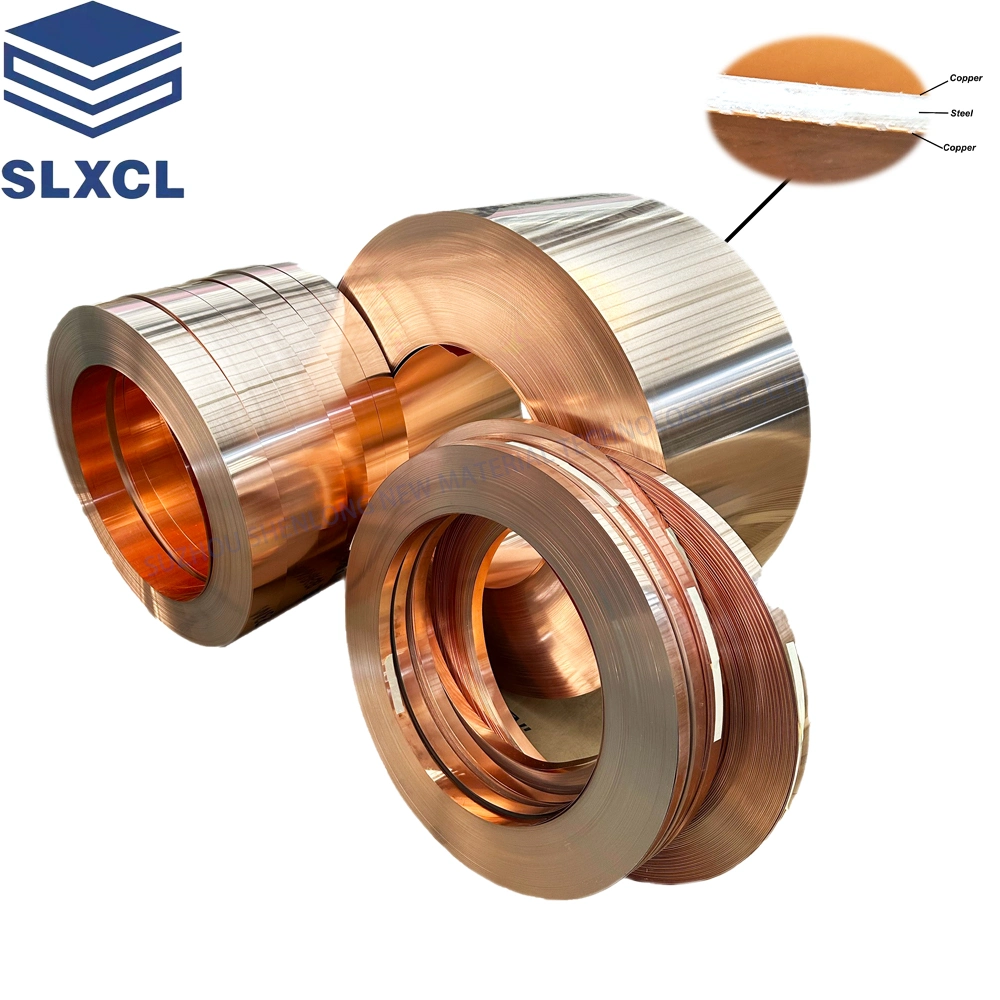

Product Series

| Copper series | Brass series |

| C1100+IF+C1100 | C2680+IF+C2680 |

| C1100+304/201+C1100 | C2200+F18/F11+C2200 |

1.Layers thickness:the total thickness is 0.05-3.1mm;accounts for 2% to 80% of the total thickness; can be composite with different cladding layer thickness on bothe sides.

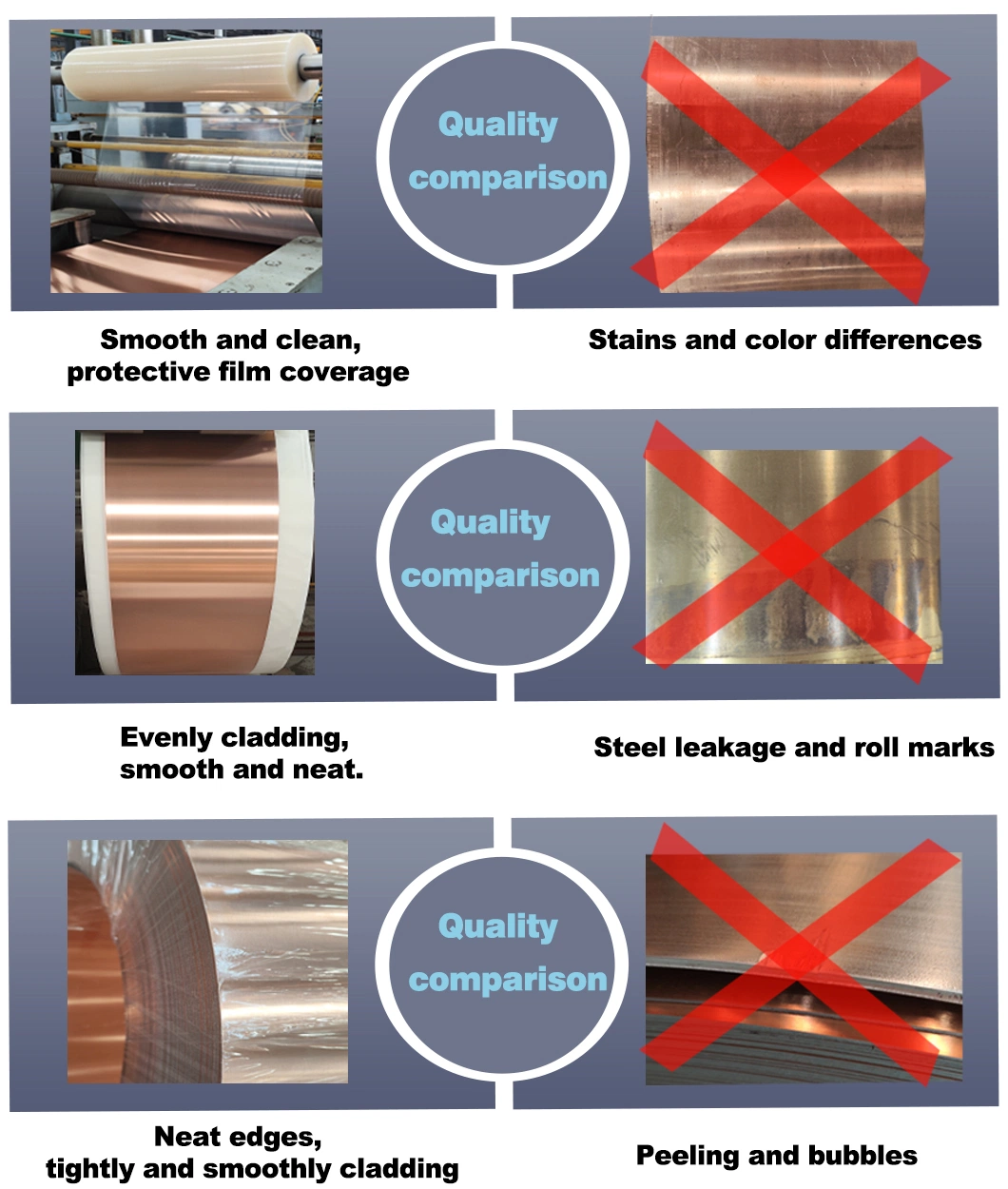

2.Quality standards:conforms to be the national standards GB13238-91 "copper-clad steel plate"and WJ 643-2016 "specification for copper-clad steel sheet of cartridge".

3.Delivery:coil maximum outer diameter Φ2000 plate:the length can be customized.

Copper Designation of Different Nations

| China | International | America | Japan | Britain | Germany |

| TU0 | - | C10100 | C1011 | - | - |

| TU1 | - | C10200 | C1020 | - | OF-Cu |

| TU3 | - | C10200 | C1020 | - | OF-Cu |

| T1 | - | C10200 | C1020 | - | OF-Cu |

| T2 | - | C11000 | C1100 | - | SE-Cu |

| T3 | - | - | C1221 | - | - |

| TP1 | - | C12000 | C1201 | - | SW-Cu |

| TP2 | - | C12000 | C1220 | - | SF-Cu |

| H62 | CuZn38 | C27400 | C2740 | - | CuZn40 |

| H65 | CuZn35 | C26800 | C2680 | C2107 | CuZn36 |

| H68 | CuZn32 | C26000 | C2600 | - | CuZn33 |

| H70 | CuZn30 | C26000 | C2600 | C2106 | CuZn30 |

| H80 | CuZn20 | C24000 | C2400 | C2103 | CuZn20 |

| H85 | CuZn15 | C23000 | C2300 | C2102 | CuZn15 |

| H90 | CuZn10 | C22000 | C2200 | C2101 | CuZn10 |

| H96 | CuZn4 | C21000 | C2100 | C2125 | CuZn5 |

Products Details

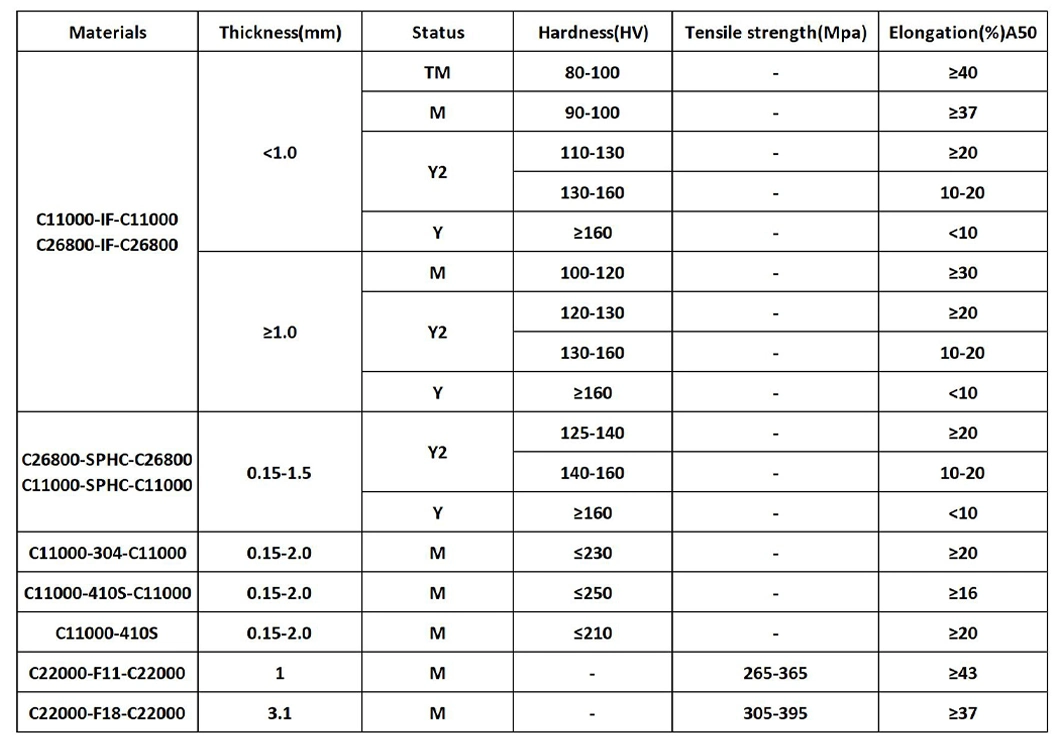

Products Parameter

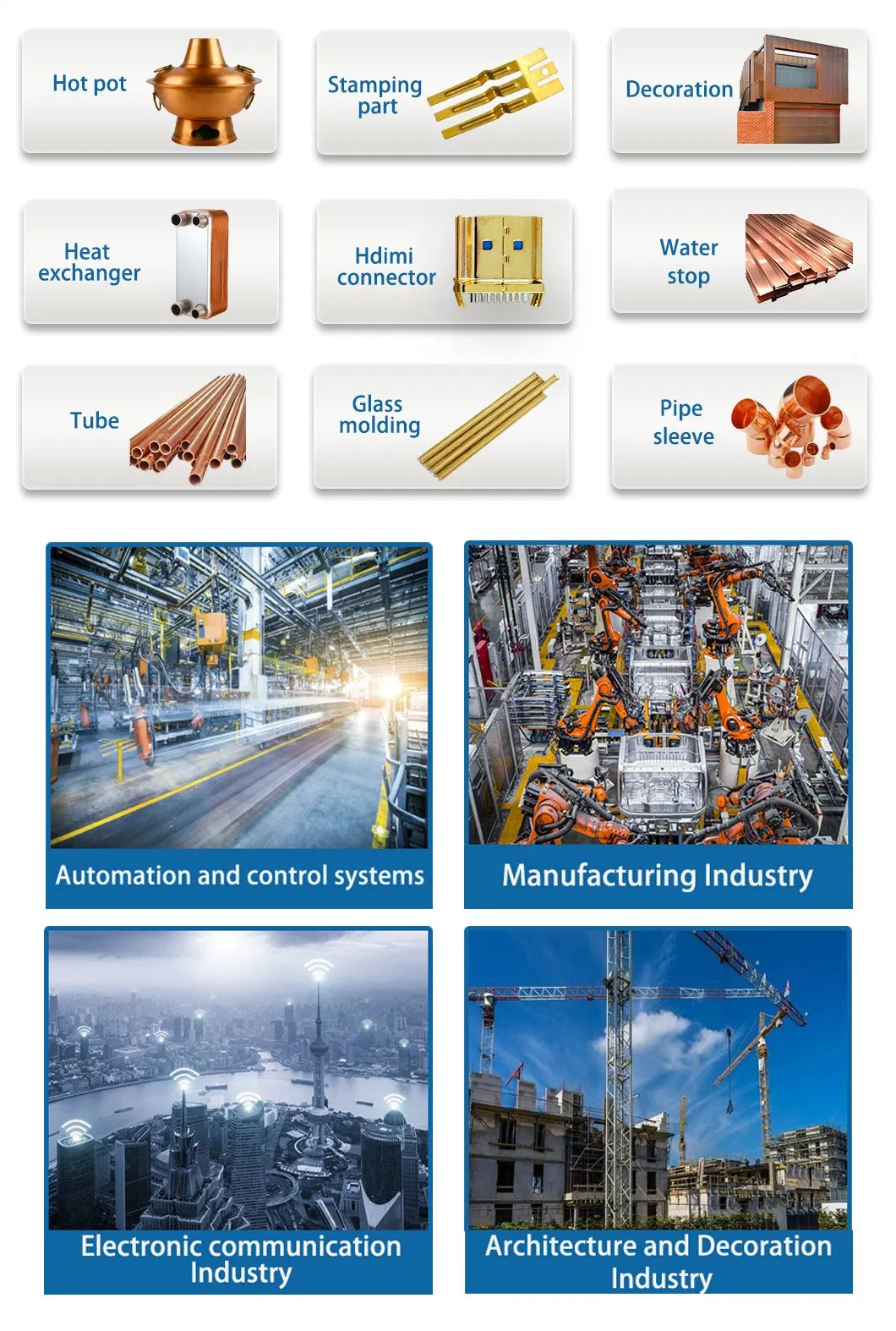

Products Applications

Company Profile

Packaging

Packaging

Q:Can i get some sample before the order ?

A:Of course, we can provide you with free sample,but the freight should be paid by customers themselves.

Q:What is the copper clad steel sheet?

A:Copper clad steel sheet is a type of composite material composed of two layers:an outer layer of copper and an inner layer of steel is bonded or clad onto the steel core using the method of hot/cold roll boinding,creating a single sheet with combined

properties of both metal.

Q:what is about your payment term?

A:We accept FOB,CIF,CFR,EXW and etc.Usually 30%deposit by T/T,70% pay against the delivery.

Q:If there are any quality problems with the products i found after using them,how to solve it?

A:First, we will engage in discussions between both parties to find a solution. Depending on the provisions of the contract and the magnitude of the issue, we will take measures such as providing compensation or offering refunds or returns to resolve the matter.

Our approach to this issue is aimed at minimizing any losses experienced by the customer.

Q:Do you test your products before delivery?

A:We have our own laboratory and professional testing personnel. After each production process, we conduct relevant inspections. For the final product, we will provide you with both hardcopy and electronic versions of the quality certificates.

Additionally, we can incorporate additional testing items according to your specific requirements at any stage of the testing process.

Q:What is the minimum order quantity?

A:Usually a roll is MOQ,weighing about 1 ton.

Q:what is the lead time ?

A:Spot delivery time is about 2-3days afer the payment.15-30days of production according to the contract quantity after receiving the deposite.

Packaging

Packaging

Q:Can i get some sample before the order ?

A:Of course, we can provide you with free sample,but the freight should be paid by customers themselves.

Q:What is the copper clad steel sheet?

A:Copper clad steel sheet is a type of composite material composed of two layers:an outer layer of copper and an inner layer of steel is bonded or clad onto the steel core using the method of hot/cold roll boinding,creating a single sheet with combined

properties of both metal.

Q:what is about your payment term?

A:We accept FOB,CIF,CFR,EXW and etc.Usually 30%deposit by T/T,70% pay against the delivery.

Q:If there are any quality problems with the products i found after using them,how to solve it?

A:First, we will engage in discussions between both parties to find a solution. Depending on the provisions of the contract and the magnitude of the issue, we will take measures such as providing compensation or offering refunds or returns to resolve the matter.

Our approach to this issue is aimed at minimizing any losses experienced by the customer.

Q:Do you test your products before delivery?

A:We have our own laboratory and professional testing personnel. After each production process, we conduct relevant inspections. For the final product, we will provide you with both hardcopy and electronic versions of the quality certificates.

Additionally, we can incorporate additional testing items according to your specific requirements at any stage of the testing process.

Q:What is the minimum order quantity?

A:Usually a roll is MOQ,weighing about 1 ton.

Q:what is the lead time ?

A:Spot delivery time is about 2-3days afer the payment.15-30days of production according to the contract quantity after receiving the deposite.