Basic Info.

Model NO.

PA FR Masterbatch

Usage

General Plastics, Engineering Plastics, Specialty Plastics

Plastic Properties After Heated

Thermoplastic Plastics

Plastic Forming Method

Injection

Color

White

Grade

Injection/Extrusion

Samples

Free

ODM/OEM

Accept

Shape

Pelltes

Quality

Stable

Transport Package

25kg/Bag

Specification

65*40*15cm

Trademark

TOPO NEW

Origin

China

Production Capacity

100kgs/Week

Packaging & Delivery

Package Size

65.00cm * 40.00cm * 15.00cm

Package Gross Weight

25.000kg

Product Description

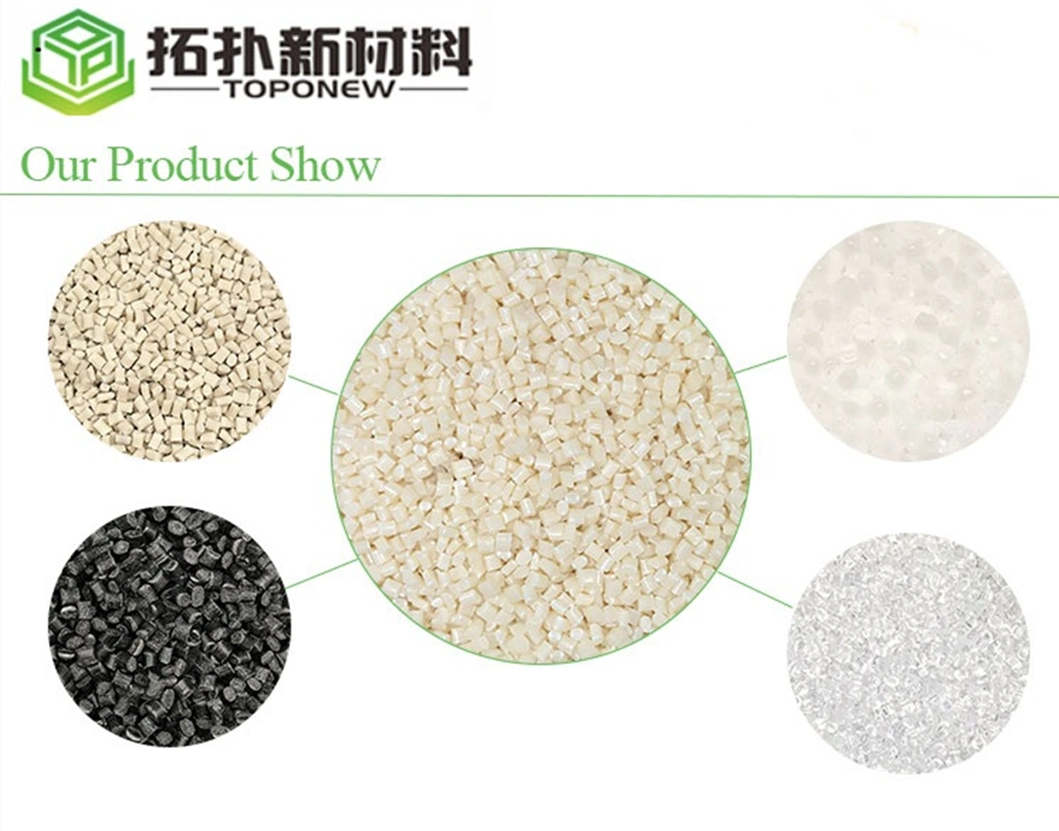

Flame retardant reinforced nylon special halogen-free flame retardant masterbatch PA-2015FR

PA-205FR is a special halogen-free flame-retardant masterbatch for flame-retardant reinforced nylon . It is a high-efficiency phosphorus-nitrogen flame-retardant masterbatch based on aluminum diethyl hypophosphite (ADP) flame retardant and compounded with phosphorus-nitrogen carbon forming system.

The flame retardant powder is coated with functional group compounds through special chemical reaction surface modification, which improves the processing thermal stability and dispersibility of the flame retardant; at the same time improves the physical and mechanical properties of flame retardant reinforced nylon products, especially It is flame retardant and enhances the moisture and heat aging resistance of nylon products.

The masterbatch of halogen-free flame retardants has enlarged the processing window of halogen-free flame-retardant reinforced nylon, making it easier to produce flame-retardant reinforced nylon products, and at the same time reducing the risk of powder dust.

Two: technical parameters

Three: Recommended dosage

Four: Precautions for use*

1: Basic formula

(1): In general, in the flame retardant reinforcement system of "nylon + flame retardant masterbatch + glass fiber " , only 0.3% of antioxidant 1098/168 or 1010/168 needs to be added to the formula.

(2): In the flame retardant reinforcement system of " nylon + flame retardant masterbatch + glass fiber " , zinc borate and silicon-based flame retardants can be added.

(3): The addition of olefin tougheners to the formula will affect the flame retardancy and glow wire GWIT value.

2: Processing technology

PA-205FR is a special halogen-free flame-retardant masterbatch for flame-retardant reinforced nylon . It is a high-efficiency phosphorus-nitrogen flame-retardant masterbatch based on aluminum diethyl hypophosphite (ADP) flame retardant and compounded with phosphorus-nitrogen carbon forming system.

The flame retardant powder is coated with functional group compounds through special chemical reaction surface modification, which improves the processing thermal stability and dispersibility of the flame retardant; at the same time improves the physical and mechanical properties of flame retardant reinforced nylon products, especially It is flame retardant and enhances the moisture and heat aging resistance of nylon products.

One: Features: The flame retardant powder is coated with functional group compounds through special chemical reaction surface modification, which improves the processing thermal stability and dispersibility of the flame retardant; at the same time improves the physical and mechanical properties of flame retardant reinforced nylon products, especially It is flame retardant and enhances the moisture and heat aging resistance of nylon products.

PA-205FR is a special halogen-free flame-retardant masterbatch for flame-retardant reinforced nylon . It is a high-efficiency phosphorus-nitrogen flame-retardant masterbatch based on aluminum diethyl hypophosphite (ADP) flame retardant and compounded with phosphorus-nitrogen carbon forming system.

The flame retardant powder is coated with functional group compounds through special chemical reaction surface modification, which improves the processing thermal stability and dispersibility of the flame retardant; at the same time improves the physical and mechanical properties of flame retardant reinforced nylon products, especially It is flame retardant and enhances the moisture and heat aging resistance of nylon products.

The masterbatch of halogen-free flame retardants has enlarged the processing window of halogen-free flame-retardant reinforced nylon, making it easier to produce flame-retardant reinforced nylon products, and at the same time reducing the risk of powder dust.

Two: technical parameters

| project | Index value |

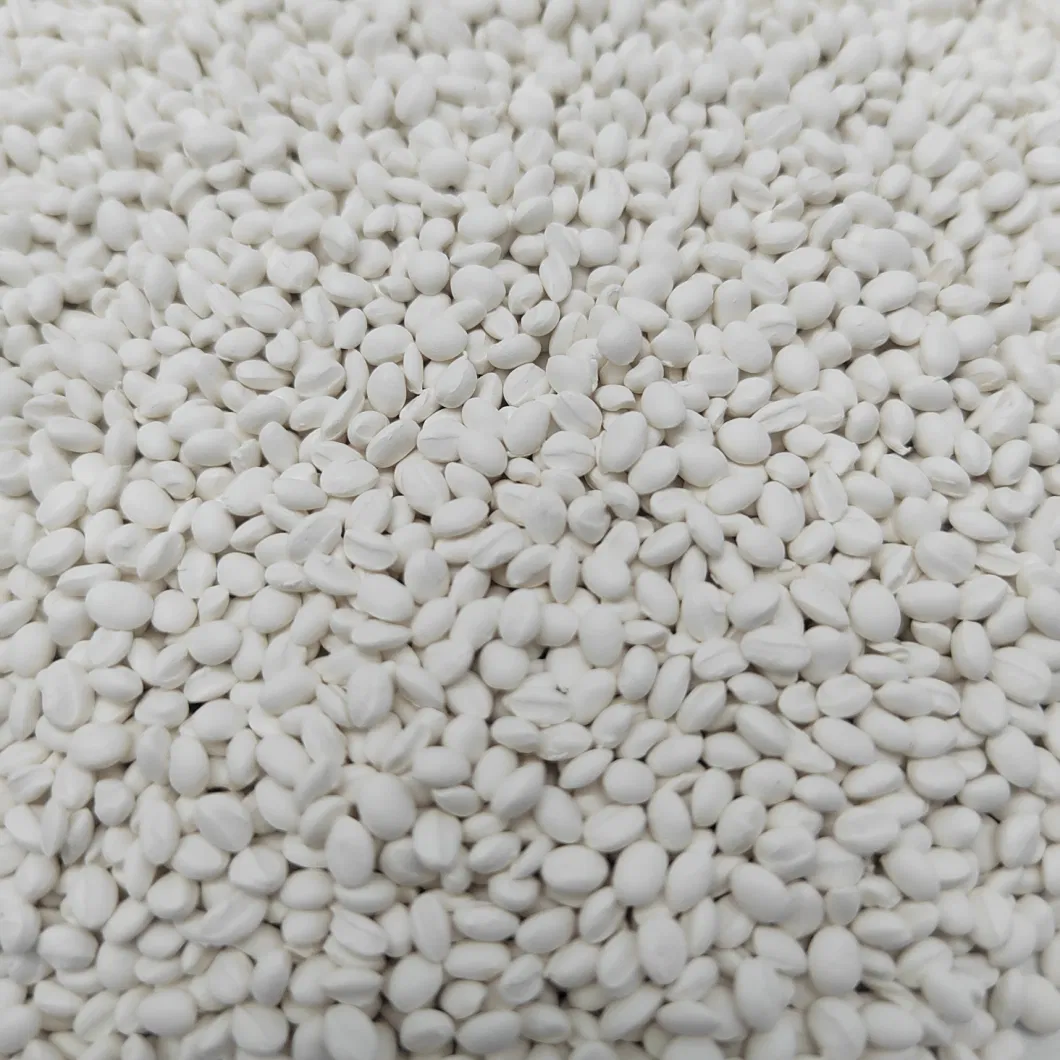

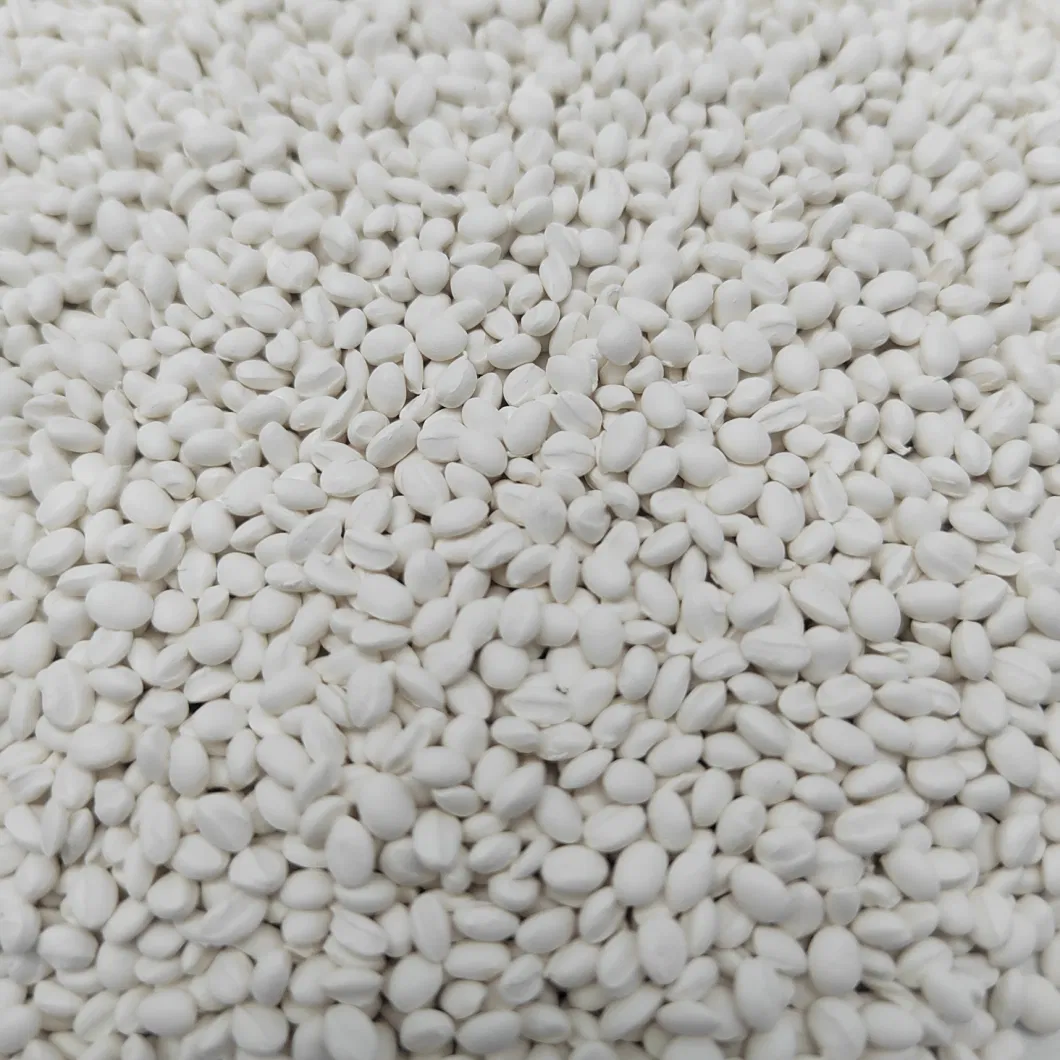

| Appearance | White particle |

| Active ingredient content | 95% |

| Moisture: | ≤02% |

Three: Recommended dosage

| product | Recommended dosage | UL-94 test |

| PA66+30%GF | 15-17% | 1.6-0.8mm V-0 |

| PA6+30%GF | 17-19% | 1.6-0.8mm V-0 |

Four: Precautions for use*

1: Basic formula

(1): In general, in the flame retardant reinforcement system of "nylon + flame retardant masterbatch + glass fiber " , only 0.3% of antioxidant 1098/168 or 1010/168 needs to be added to the formula.

(2): In the flame retardant reinforcement system of " nylon + flame retardant masterbatch + glass fiber " , zinc borate and silicon-based flame retardants can be added.

(3): The addition of olefin tougheners to the formula will affect the flame retardancy and glow wire GWIT value.

2: Processing technology

- : The flame retardant masterbatch can be mixed with all materials such as nylon, and then added at the main feeding port of the twin-screw extruder; the side feeding method is preferred to add the flame retardant masterbatch.

- : The screw speed of the twin-screw extruder should not be too high, so as to avoid the decomposition of the flame retardant caused by high shear heat.

- : The temperature of each heating zone after the extruder adds glass fiber section can be lowered appropriately, it is recommended to set it above the melting point of nylon.

Are you a trading company or manufacturer?

We are a manufacturer.

About Sample?

A 5 KG Free Sample can be offered per your request.

About Material Color?

We can make the material to your appointed color according to Pantone/RAL#.

How does your factory control the quality?

Quality is the Priority, we always pay great importance to quality from beginning to end, we have professional QC for item quality from spare parts to finished goods.

How many days for mass production?

20 days after all artwork and 30% deposit are confirmed.

How can I get the samples? Is the sample free?

7-10 days to send free samples by DHL, TNT, and UPS.