Basic Info.

Model NO.

A-930

Kind

Nucleating Agent

Appearance

Granulars

Name

PP Nucleating Masterbatch

Performance

Improve PP Clearancy Transparency

Free Sample

Yes

Addition Percentage

2-4%

Manufacture

Yes

Warranty

3 Years

Model

a-930

Certificate

MSDS

Application

PP Cup Bottles Films Container etc

Carrier Resin

PP

Transport Package

Woven Bag

Specification

25kg/bag

Trademark

Argiope

Origin

Guangdong

Production Capacity

5000000 Tons/ Year

Product Description

plastic factories in turkey transparency clarifying agent for PP nucleating masterbatch

Function of PP nucleating masterbatch

1) Mainly For improving transparency / clarity / crystalization and slightly improve stiffness of PP plastics product

2) slightly improve the production speed and thus improve production circle

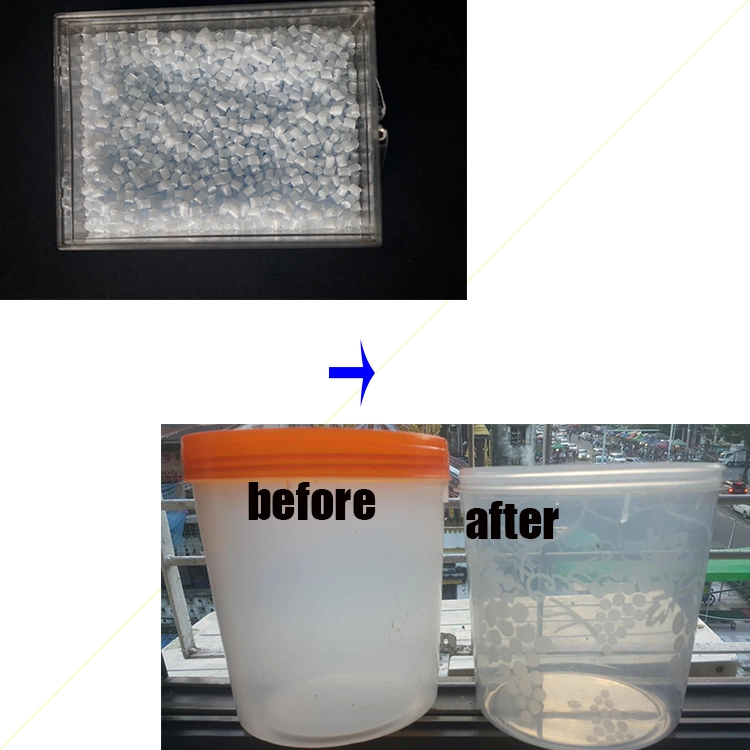

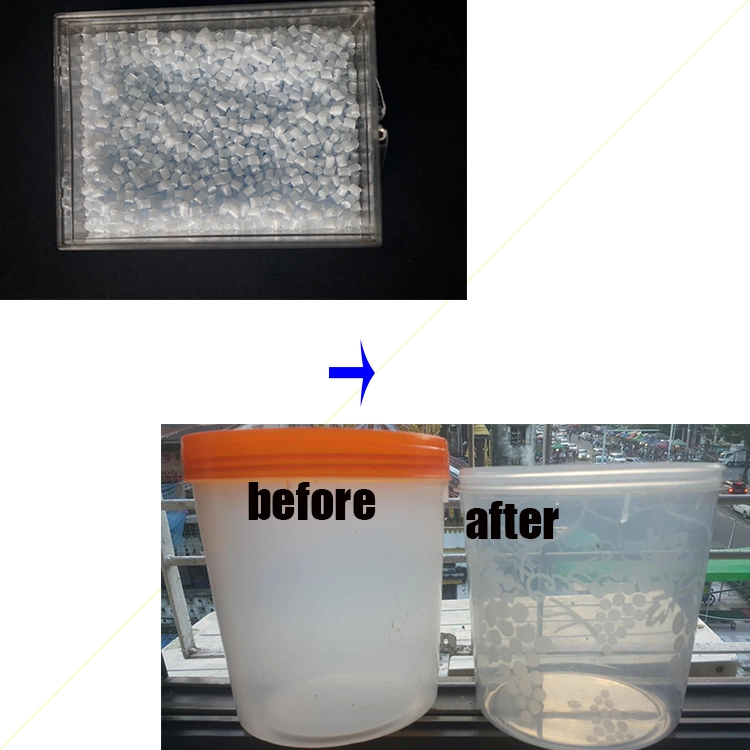

3) please chck PP container transparency before and after adding our clarifying agent

Datasheet of PP nucleating masterbatch

Applications of PP nucleating masterbatch

Picture of PP nucleating masterbatch

Advantage of PP nucleating masterbatch

1. Functional nucleating masterbatch additives---improving transparency / clarity / crystalization / stiffness

2. -our Nucleating Agent low dosage.2%--4% ,PP clarity / transparency / clearancy could get 40%--70% improvement while with no effect on other properties.

3. Good compatibility and dispersion with the plastics polymers PP, no precipitation or layerings after adding.

4. no calcium content or other fillers, 99.9% effected components ensures high performance

Company Information

Shenzhen Jindaquan Factory is the Chinese enterprise who brings out "plastic toughening agent" concept in 2008, Specializing in improving the plastic impact strength, tougheness, elongation, low temperature resistance and flexibility. This greatly distinguishes from the general rough concept of "Plasticizer"

Our enterprise built in 1998, focusing on Plastic color masterbatch and pigments, In 2008 jindaquan chemical was built, we made big revolution by investing techniques in Plastic chemical Anxiliary. Create ALLGONG® and ARGIOPE® brand "plastic toughening agent / impact modifier" with innovative extremely low dosage 0.2%-4% ever in the plasticizer industry. Until now our product line including Impact Modifiers /Toughening agents, Brightening Agents, Flame Retardants, MFI Modifier, Gloss additive, Nucleating Agent, Light Difussion Agent, Matt Agent, Color masterbatch, Pigment , Engineering Plastics, Anti UV and Stabilizers ect.

FAQ

1. Can i get free sample?

Yes, we could offer free sample for test with shipping freight collect. Sample will be shipped out with your delivery address provided.

2. How to order?

First please send us an inquiry by telling your plastic materials, products and the desired effect to get by adding the additives. Then we will soon reply and advise perfect additives for you. And free sample will be shipped out with your confirmation. Once get the effective test result, prices could be negotiated for big order. Delivery time 1-7 working days for bulk order once payment received.

3. What's your warranty?

3 years warranty.

4. How to add your additives?

Mix our additives evenly with your materials around 8-10 min.

To test the results of adding impact modifier, please wait for at least 24 hours after extrusion, injection molding or blow molding , for the effect is much more obvious at that time

5. Can you specially create formulation for our special demands?

Yes, we have professional engineer team to work for you

6. Will your impact modifiers effect the transparency and other properties ?

We have liquids and transparent masterbatch form of impact modifiers which has no effect on the transparency. About other properties, as our dosage is really low as 1% of raw materials, this negative effects could be neglected.

7. What certificates you have ?

FOOD GRADE / REACH/ROHS/ISO9001:2008/EZT121/PHTHALATES/EN71.3/EN1.122

Certificate

Function of PP nucleating masterbatch

1) Mainly For improving transparency / clarity / crystalization and slightly improve stiffness of PP plastics product

2) slightly improve the production speed and thus improve production circle

3) please chck PP container transparency before and after adding our clarifying agent

Datasheet of PP nucleating masterbatch

| Density | 1.03g/cm3 |

| MFI | 60g/10min |

| Addition Percentage | 2-4% |

| Appearance | Masterbatch granule |

| Application | injection , extrusion, blowing molding etc |

Applications of PP nucleating masterbatch

Picture of PP nucleating masterbatch

Advantage of PP nucleating masterbatch

1. Functional nucleating masterbatch additives---improving transparency / clarity / crystalization / stiffness

2. -our Nucleating Agent low dosage.2%--4% ,PP clarity / transparency / clearancy could get 40%--70% improvement while with no effect on other properties.

3. Good compatibility and dispersion with the plastics polymers PP, no precipitation or layerings after adding.

4. no calcium content or other fillers, 99.9% effected components ensures high performance

Company Information

Shenzhen Jindaquan Factory is the Chinese enterprise who brings out "plastic toughening agent" concept in 2008, Specializing in improving the plastic impact strength, tougheness, elongation, low temperature resistance and flexibility. This greatly distinguishes from the general rough concept of "Plasticizer"

Our enterprise built in 1998, focusing on Plastic color masterbatch and pigments, In 2008 jindaquan chemical was built, we made big revolution by investing techniques in Plastic chemical Anxiliary. Create ALLGONG® and ARGIOPE® brand "plastic toughening agent / impact modifier" with innovative extremely low dosage 0.2%-4% ever in the plasticizer industry. Until now our product line including Impact Modifiers /Toughening agents, Brightening Agents, Flame Retardants, MFI Modifier, Gloss additive, Nucleating Agent, Light Difussion Agent, Matt Agent, Color masterbatch, Pigment , Engineering Plastics, Anti UV and Stabilizers ect.

FAQ

1. Can i get free sample?

Yes, we could offer free sample for test with shipping freight collect. Sample will be shipped out with your delivery address provided.

2. How to order?

First please send us an inquiry by telling your plastic materials, products and the desired effect to get by adding the additives. Then we will soon reply and advise perfect additives for you. And free sample will be shipped out with your confirmation. Once get the effective test result, prices could be negotiated for big order. Delivery time 1-7 working days for bulk order once payment received.

3. What's your warranty?

3 years warranty.

4. How to add your additives?

Mix our additives evenly with your materials around 8-10 min.

To test the results of adding impact modifier, please wait for at least 24 hours after extrusion, injection molding or blow molding , for the effect is much more obvious at that time

5. Can you specially create formulation for our special demands?

Yes, we have professional engineer team to work for you

6. Will your impact modifiers effect the transparency and other properties ?

We have liquids and transparent masterbatch form of impact modifiers which has no effect on the transparency. About other properties, as our dosage is really low as 1% of raw materials, this negative effects could be neglected.

7. What certificates you have ?

FOOD GRADE / REACH/ROHS/ISO9001:2008/EZT121/PHTHALATES/EN71.3/EN1.122

Certificate