- Overview

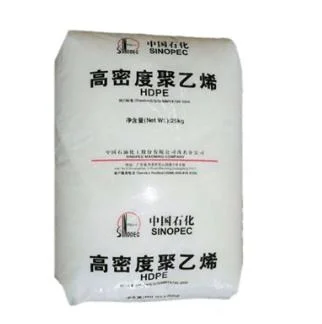

- Product Description

- Detailed Photos

- Product Parameters

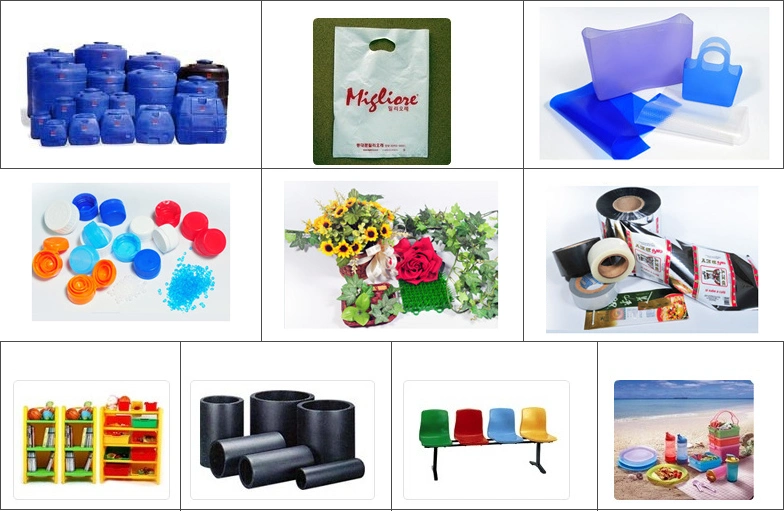

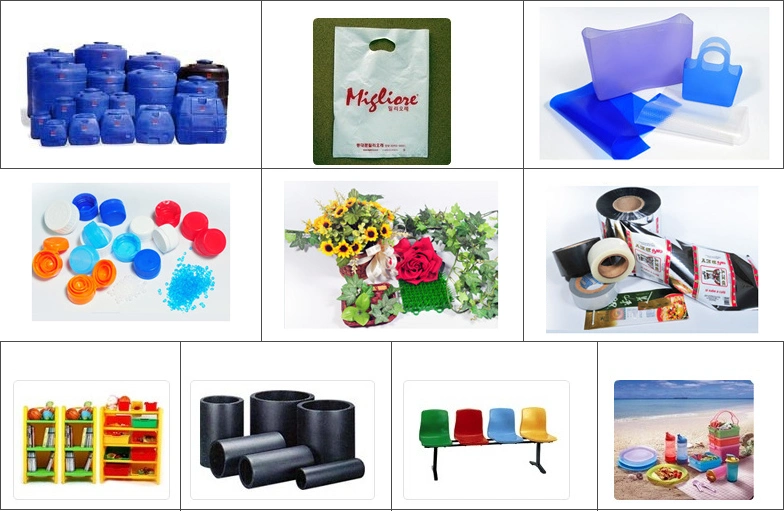

- Application

- Packaging & Shipping

- product display

- FAQ

Basic Info.

Model NO.

HDPE04

Usage

General Plastics

Application

Raw Material

Feature

Virgin Film Injection Grade

Transport Package

25kg/Bag

Specification

plastic

Trademark

JIANGZHI

Origin

Hebei

HS Code

390110009

Production Capacity

50000ton/Month

Product Description

High density Polyethylene (HDPE): is a highly crystalline non-polar thermoplastic resin produced through the copolymerization of

ethylene and a small amount of α-olefin monomer. HDPE is synthesized under low pressure and is therefore also called low-pressure

polyethylene. HDPE is mainly a linear molecular structure and has little branching. It has a high degree of crystallization and

high density. It can withstand high temperatures and has good rigidity and mechanical strength and anti-chemical corrosion.

HDPE applications, including film, blow-molding, extrusion molding, injection molding, pipes, wire & cable and base material for

producing chlorinated polyethylene.

2.Film ( shopping bags, casting film, multilayer film, etc.)

3.Blow Molding ( Medical & Cosmetic container, Lubricant & Paint container, etc)

4.Extrusion Molding ( Sheet, Pipe, Wire & Cable, etc.)

5.Injection Molding ( Automotive, Electronic, Construction, House wares, Furniture,

Toys, etc.)

ethylene and a small amount of α-olefin monomer. HDPE is synthesized under low pressure and is therefore also called low-pressure

polyethylene. HDPE is mainly a linear molecular structure and has little branching. It has a high degree of crystallization and

high density. It can withstand high temperatures and has good rigidity and mechanical strength and anti-chemical corrosion.

HDPE applications, including film, blow-molding, extrusion molding, injection molding, pipes, wire & cable and base material for

producing chlorinated polyethylene.

Prometer Information

Product Name: Plastic Pellets hdpe

Material: Plastic Raw Material Granule

Shape: Pellet - Granules

Color: Natural/customized

Applicable process: Injection molding, modification

Feature: Heat resistance, cold resistance, corrosion resistance, impact resistance, easy to process, good epidemic

Product Name: Plastic Pellets hdpe

Material: Plastic Raw Material Granule

Shape: Pellet - Granules

Color: Natural/customized

Applicable process: Injection molding, modification

Feature: Heat resistance, cold resistance, corrosion resistance, impact resistance, easy to process, good epidemic

| Performance of the project | Test condition [condition] | The test method | The test data | The data unit | |

| Basic performance | Density mass index | | GB/T 1033 | 0.948±0.002 | g/cm3 |

| Density test results | | GB/T 1033 | 0.948 | g/cm4 | |

| Melt flow rate mass index | 190ºC/5.0kg | GB/T 3682 | 0.23±0.03 | g/10min | |

| Melt flow rate test results | | GB/T 3682 | 0.25 | g/10min | |

| Melt flow rate mass index | 190ºC/21.6kg | GB/T 3682 | 6.2±1.5 | g/10min | |

| Melt flow rate test results | | GB/T 3682 | 6.4 | g/10min | |

| Mechanical properties of | Tensile yield strength quality index | | GB/T 1040 | ≥23 | MPa |

| Test results of tensile yield strength | | GB/T 1040 | 27.6 | MPa | |

| Elongation at break quality index | | GB/T 1040 | ≥600 | % | |

| Test results of elongation at break | | GB/T 1040 | 804 | % | |

| Quality index of impact strength of simply supported beam | | GB/T 1043 | ≥25 | KJ/m2 | |

| Test results of impact strength of simply supported beam | | GB/T 1043 | 26.7 | KJ/m2 | |

| Other properties | Volatile matter quality index | | GB/T 15658 1 | ≤350 | mg/kg |

| Volatile test results | | GB/T 15658 1 | Did not check out | mg/kg | |

| Biochemical property | Cleanliness (color granule) quality index | | SH/T 1541 | ≤20 | grain/kg |

| Cleanliness (color particle) test results | | SH/T 1541 | 0 | grain/kg | |

| Cleanliness (impurities) quality index | | SH/T 1541 | ≤60 | grain/kg | |

| Cleanliness (impurities) test results | | SH/T 1541 | 0 | grain/kg | |

1.Fiber ( Carpet, Textils, Upholstery, etc.)

2.Film ( shopping bags, casting film, multilayer film, etc.)

3.Blow Molding ( Medical & Cosmetic container, Lubricant & Paint container, etc)

4.Extrusion Molding ( Sheet, Pipe, Wire & Cable, etc.)

5.Injection Molding ( Automotive, Electronic, Construction, House wares, Furniture,

Toys, etc.)

25kg/ carton or 25kg/bag, or per your requirement

25kgs net weight in PP woven or PE plastic bag about 20 tons for 20" container

1.We are able to provide customized service based on your requirements.

2. Competitive prices - directly from factory to customer.

3.Advanced equipments for testing and manufacturing.

4.Professional and good after-sale service

5. Free sample for testing